TL;DR Quick Answers

restaurant kitchen management

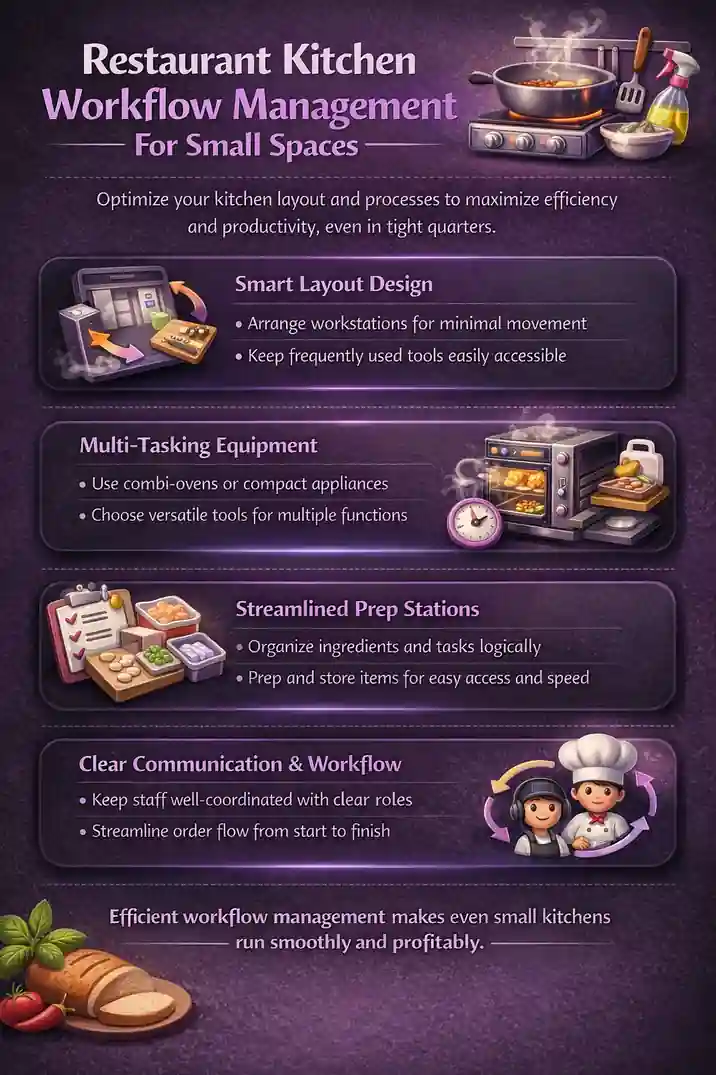

Restaurant kitchen management is the practice of controlling workflow, people, and processes so food moves safely and efficiently from prep to service. In real kitchens, success comes from intentional flow—clear station ownership, front-loaded prep, and reduced movement—especially in small spaces where inefficiency shows up fast. When managed well, kitchens run faster, safer, and with lower labor pressure, without needing more space or staff.

Top Takeaways

Workflow matters more than space.

Small kitchens succeed or fail based on flow—not square footage.Clear flow reduces chaos.

Defined paths, stations, and prep improve speed, safety, and consistency.Most issues are process-related.

Delays and mistakes usually come from poor sequencing, not staff effort.Efficiency comes from doing less.

Fewer steps, handoffs, and overlaps outperform adding staff or equipment.Small kitchens can outperform large ones.

When workflow is intentional, compact kitchens handle volume with lower stress and better margins.

Why Workflow Matters More Than Square Footage

In small restaurant kitchens, workflow—not size—is the deciding factor between smooth service and constant delays. Limited space magnifies every inefficiency: extra steps, unclear station boundaries, and poorly timed prep quickly turn into congestion and missed tickets. Effective workflow management focuses on controlling movement, sequencing tasks correctly, and ensuring every station operates with purpose.

Designing a Linear, Low-Collision Kitchen Flow

The most successful small kitchens follow a linear workflow—ingredients move forward from storage to prep, cooking, plating, and service without backtracking. This reduces cross-traffic, prevents staff collisions, and keeps food moving in one clean direction. Clear station zoning, even within tight quarters, helps cooks stay focused and eliminates confusion during peak hours.

Optimizing Stations for Speed and Accountability

In compact kitchens, stations must be multi-functional but clearly owned. Each cook should know exactly what they’re responsible for, with tools and ingredients positioned within arm’s reach, reflecting the same discipline found in owning а smаll farmfis where space, roles, and efficiency must be managed carefully every day. Streamlined stations reduce unnecessary movement and allow staff to execute faster, even with fewer people on the line.

Using Prep Strategy to Reduce Line Pressure

Smart workflow starts long before service. Small kitchens rely heavily on front-loaded prep, batching tasks during off-peak hours to minimize congestion during rushes. Proper prep timing, labeling, and storage placement ensure cooks spend service time cooking—not searching or assembling.

Leveraging Equipment Placement and Vertical Space

Efficient workflow also depends on equipment layout. High-use tools should be closest to their primary station, while vertical storage—shelves, wall-mounted racks, and overhead storage—frees up valuable floor space. The goal is to reduce steps, not add storage clutter.

Creating a Kitchen That Scales Without Expanding

When workflow is dialed in, small kitchens can handle higher volume without adding square footage or staff. Clear flow paths, disciplined station roles, and intentional prep systems supported by a kitchen brigade system allow compact kitchens to operate with the speed and consistency of much larger operations.

“In most small kitchens we’ve worked inside, the biggest problem isn’t the lack of space—it’s the lack of intentional flow. When you map how cooks actually move during service, you almost always find wasted steps and overlapping tasks. Once those are removed, even the tightest kitchens start running faster, calmer, and more consistently without changing the footprint.”

Essential Resources

Running a kitchen — especially a small one — means more than hot stoves and plated food. It’s about systems, tools, and processes that work when the line is slammed and ticket times are tight. The following resources are trusted by chefs and kitchen leaders for managing workflow, costs, safety, and performance on the line and behind the scenes.

1. How to Run a Restaurant Kitchen Efficiently (Restaurant Times)

Stay ahead of operational chaos

A chef-friendly breakdown of core kitchen systems that keep orders moving, reduce friction between stations, and streamline back-of-house workflow. Ideal for identifying bottlenecks and standardizing daily processes.

https://www.restauranttimes.com/blogs/operations/how-to-run-a-restaurant-kitchen-efficiently/

3. National Restaurant Association – Operations & Education

Industry benchmarks and professional standards

Provides research, certification programs, and operational best practices that help kitchen leaders make informed decisions rooted in industry data and compliance standards.

https://www.restaurant.org/

4. Kitchen Management Best Practices (UpMenu)

Connect theory to the day-to-day grind

Explains how workflow design, staffing logistics, inventory handling, and modern kitchen tools work together to create smoother, more predictable service.

https://www.upmenu.com/blog/kitchen-management/

5. Comprehensive Guide to Running an Efficient Kitchen (TapTasty)

Clear frameworks for organizing people and space

Offers a practical overview of kitchen organization and communication principles, helping managers visualize station flow and identify where efficiency gains matter most.

https://www.taptasty.com/blog/kitchen-management-comprehensive-guide-to-efficiently-run-your-kitchen/

6. Must-Read Restaurant Management Books (Eat App)

Build depth in leadership and operational thinking

A curated reading list that expands knowledge beyond daily kitchen tasks, covering leadership, systems thinking, and long-term restaurant success.

https://restaurant.eatapp.co/blog/restaurant-management-books

7. Kitchen Organization Tools for Faster Service (Toast)

Tools that improve workflow immediately

Highlights practical organization and technology tools that reduce clutter, improve communication, and support faster service in high-pressure, space-limited kitchens.

https://pos.toasttab.com/blog/on-the-line/restaurant-kitchen-organization-tools

Supporting Statistics

The data below reinforces what chefs and kitchen managers consistently see on the line: workflow failures—not effort—drive safety risks, food safety issues, and rising costs in small kitchens. These U.S.-based statistics support why intentional kitchen flow matters.

1. Tight kitchens increase injury risk when flow breaks down

2.4 recordable injuries per 100 full-time workers in Food Services (BLS, NAICS 722).

Congested walk paths and overlapping stations increase collisions during rushes.

Cleaner flow reduces accidents, fatigue, and service slowdowns.

Source: https://www.bls.gov/iif/nonfatal-injuries-and-illnesses-tables/table-1-injury-and-illness-rates-by-industry-2023-national.htm

2. Food safety issues often start with process failures

48 million foodborne illnesses annually in the U.S. (CDC).

128,000 hospitalizations and 3,000 deaths each year.

In practice, breakdowns happen during rushed prep, labeling lapses, and shared surfaces.

Structured prep flow and station discipline reduce risk.

Source: https://www.cdc.gov/food-safety/data-research/facts-stats/index.html

3. Norovirus spreads fastest where workflow overlaps

Causes 58% of U.S. foodborne illnesses (CDC).

About 2,500 outbreaks annually.

Common causes in real kitchens:

Handwashing stations too far from work zones

Dish flow crossing prep areas

Backtracking during peak service

Purpose-built workflow limits exposure points.

Source: https://www.cdc.gov/norovirus/data-research/index.html

4. Poor workflow quietly drains labor margins

36.5% of sales go to labor in full-service restaurants (National Restaurant Association).

Inefficient kitchens lose money through:

Extra steps and wasted motion

Ticket delays

Overstaffing to compensate for chaos

Intentional flow often allows the same volume with fewer staff.

Source: https://restaurant.org/research-and-media/research/restaurant-economic-insights/analysis-commentary/elevated-labor-costs-had-a-significant-impact-on-restaurant-profitability-in-2024/

Together, these statistics show that workflow design directly affects safety, food handling, and labor costs in small kitchens, where handling delicate proteins like hake fish requires clear station flow, proper handoff, and disciplined prep routines to prevent contamination, injuries, and costly slowdowns under pressure.

Final Thought & Opinion

After working inside and alongside small restaurant kitchens, one reality stands out fast: space is rarely the real issue—workflow is. Some of the most efficient kitchens we’ve seen operate in tight footprints because movement, timing, and responsibility are intentionally designed.

What separates efficient small kitchens from chaotic ones

It isn’t more staff, equipment, or square footage. It’s discipline.

Efficient kitchens focus on:

Clear flow paths that reduce collisions and backtracking

Prep done with purpose, before service pressure hits

Stations designed around how cooks actually work during a rush

The most common mistake operators make

Many kitchens try to add their way out of workflow problems.

From experience, this often means:

Adding staff to compensate for poor flow

Adding equipment that increases congestion

Adding storage instead of removing unnecessary steps

What actually works in small kitchens

The biggest gains usually come from subtraction.

High-performing small kitchens prioritize:

Fewer steps between tasks

Fewer handoffs between stations

Fewer overlapping responsibilities

Final takeaway

A small kitchen with intentional workflow will consistently outperform a larger kitchen without one. Control the flow, and you gain control over safety, consistency, and margins—without expanding the space or the payroll.

FAQ on Restaurant Kitchen Management

Q: What does restaurant kitchen management control day to day?

A: It controls workflow. How cooks move. Where prep happens. Who owns each station. How work flows when the line is under pressure.

Q: Why do small kitchens break down faster during service?

A: Inefficiency is amplified. Extra steps create delays. Shared surfaces cause congestion. Unclear roles increase stress. Clean flow prevents chaos.

Q: What’s the fastest way to improve kitchen workflow without remodeling?

A: Observe a busy service. Track unnecessary steps. Tighten station boundaries. Reposition high-use tools. Shift more work to prep time.

Q: What mistakes appear most often in kitchen management?

A: Trying to add instead of fix. Adding staff. Adding equipment. Adding storage. These usually increase congestion rather than solve it.

Q: How does better kitchen management protect margins and food safety?

A: Controlled flow delivers results. Fewer mistakes. Better sanitation. Faster tickets. Lower labor pressure.